Download Computer Integrated Manufacturing: From Fundamentals to Implementation - Alan Weatherall | ePub

Related searches:

What is computer-integrated manufacturing? computer-integrated manufacturing uses computers to automatically control every aspect of the production process, using real-time input from sensors. This approach can result in speedier production and minimal errors.

Computer integrated manufacturing: from concepts to realisation is an approachable and essential text for mechanical, manufacturing and industrial engineering.

18 oct 2012 cim is the integration of all enterprise operationsand activities around a common corporate datarepository.

Computer-integrated manufacturing (cim) is een concept waar een volledig productieproces digitaal wordt georganiseerd in een computersysteem.

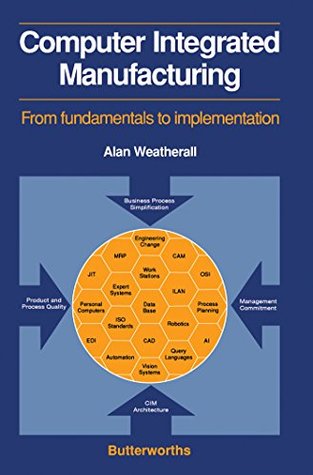

What is computer-integrated manufacturing (cim)� computer-integrated manufacturing (cim), as the name suggests, integrates the software and hardware needed for computer graphics, computer-aided modeling, and computer-aided design and manufacturing activities, from initial product concept through its production and distribution in the marketplace.

2 jul 2019 computer-integrated manufacturing (cim) is the process of using computers to automate the manufacturing process of a product.

System (cms) four-plan concept of manufacturing cim system discussed: computer numerical control (cnc) direct numerical control (dnc) computer process control computer integrated production management.

Recent progress in japanese computer-integrated manufacturing (cim) includes the integration of computer graphics, database management systems, local.

Computer-integrated manufacturing uses computers to automatically control every aspect of the production process, using real-time input from sensors. This approach can result in speedier production and minimal errors. It works best when the production process is highly standardized and there is no variation in the output required from the process.

Computer-integrated manufacturing (cim) refers to the use of computer- controlled machineries and automation systems in manufacturing products.

A computer-integrated manufacturing system is not the same as a lights-out factory, whi h ld l t l i d d t f hhich would run completely independent of human intervention, although it is a big step in that direction part of the system involves flexible manufacturing, where the factory can be quickly modified to produce different.

In straightforward terms, cim is the technique of using computers to control an entire production process.

The integration of product design techniques and manufacturing fundamental principles, along with a look at changing operations and information systems that support cim throughout the enterprise, make computer-integrated manufacturing unique.

Vital to today's manufacturing processes, this book shows how cim fits into the current manuafacturing systems and how the technology is used to solve real-world industrial problems. This is the only technology level text in computer-integrated manufacturing.

Definition of cim“cim is the integration of the totalmanufacturing enterprise through the useof integrated systems and datacommunications coupled with newmanagerial philosophies that improveorganizational and personnel efficiency. ”computer-integrated manufacturing (cim)is the manufacturing approach ofusing computers to control the entireproduction process.

Computer integrated manufacturing (cim) system has several key components: an automated storage and retrieval system (asrs), at least one automated.

Computer integrated manufacturing (cim) can be considered as an advanced business philosophy that unifies a company's administration, engineering and manufacturing. The information technology plays a central role for planning and controlling the manufacturing process.

Computer-integrated manufacturing includes all the engineering functions of cad/cam and the business functions of the firm as well.

Computer-integrated manufacturing (cim) refers to the use of computer-controlled machineries and automation systems in manufacturing products.

Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. The term computer-integrated manufacturing is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized.

Computer-integrated manufacturing (cim) is the manufacturing approach of using computers to control entire production process.

Abstract: in today's manufacturing environment, competition and technological advances affect both products.

Computer-integrated manufacturing, data-driven automation that affects all systems or subsystems within a manufacturing environment: design and development, production (see cad/cam), marketing and sales, and field support and service.

Computer-integrated manufacturing (cim), as the name suggests, integrates the software and hardware needed for computer graphics, computer-aided modeling, and computer-aided design and manufacturing activities, from initial product concept through its production and distribution in the marketplace.

Computer integrated manufacturing, cim study materials, engineering class handwritten notes, exam notes, previous year questions, pdf free download.

Post Your Comments: